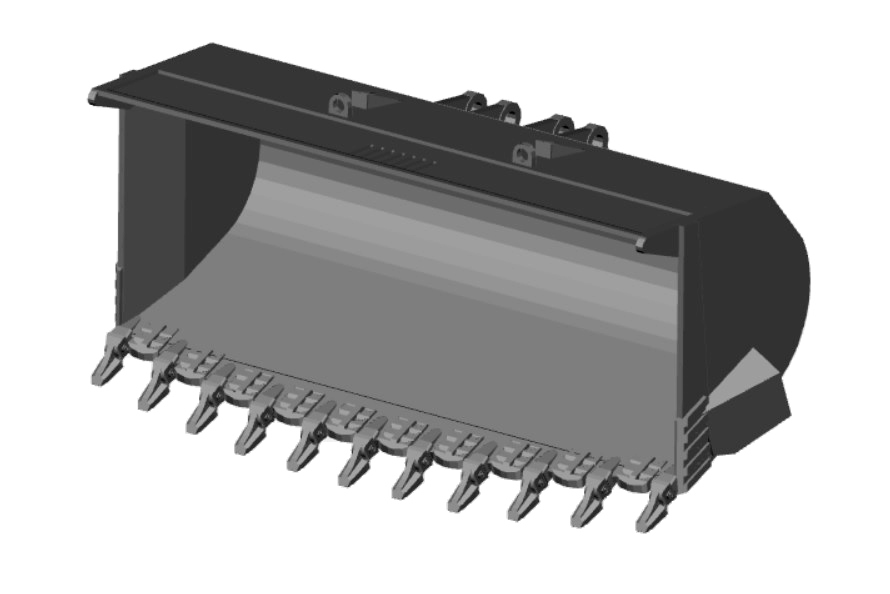

Rock buckets XHD

Rock buckets are are successfully applied for loaders above 18 tons. The optimum usage for mining works, works with waste material with high abrasion at density ober the 2000 Kg/m3. The structure is focused on usage for quarry works. Buckets are designed for easy penetrating into the material, loading of slag. For buckets production we use the highest quality materials (Hardox, Weldox, Borox). The stiff system of bucket clamping and low deformity of frame ensures optimum functionality.

The design of rock bucket is according to its usage made with straight or vee-shaped cutting edge with fixed or detachable teeth and possibility of usage the teeth edge protection.

Specification and parameters:

- Optional teeth systems CATERPILLAR, J.C.B., BOFORS, VOLVO, KOMATSU, FIAT, ESCO, MTG, CASE, MASSEY FERGUSSON, NEW HOLLAND, JOHN DEERE, HYUNDAI, JOHN DEERE, UNI-Z, DOOSAN, HENSLEY optimized for durability and effectiveness of penetrating into the material.

- Improved design for high-stress and maximum usage of loader options.

- Clever side edge and thickened bottom designed for equal abrasion and extended time of usage.

- Bucket design is proposed for maximum toughness and resistivity against impacts and dynamic stress.

- Buckets structure is carefully elaborated and applied after demanding tests for easy penetrating into the material, dump with cleansing action.

- Abrasion elements in the exposed places (edge protection, teeth board, chocky bars, abrasion protection)