The experiences of Delta HL with implementing the innovative projects

The company DELTA HL constantly makes an effort to improve the quality of their services and adapt them to clients needs. Thanks to own development and design they are offering to clients the technical solutions, that correspond the best to client´s requests. Progressive improvement the quality of the services and products belongs to the highest priority of the company. The summary sheet presents the innovative projects, that are related to production of components for concrete pumps. At the execution of a development projects were bought the CNC machines.

| Name | Description |

|---|---|

|

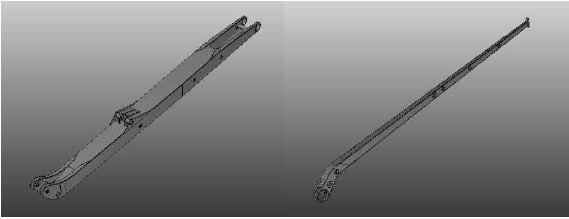

Innovation of quiding the telescopic jibs |

The aim of innovation quiding the telescopic jibs was increasing their utility characters – increasing the strength and reach and also weight decreasing |

|

Innovation of trolley bus TB 112 axle |

Innovation and design the critical knots of the weldment with regard to longer axle lifetime – higher fatigue strength |

|

Innovation the building machinery jibs from high-strength fine-grain steel S700 MC, S890 QL, S960 QL |

Innovation the building machinery jibs 1, 2, 3, 4 consisted in the design of high-strength steel semi-finished product with yield strength Reh = 700 Mpa, 890 Mpa and 960 Mpa, the the higher strength was reached and the weight of jibs framework was substantially decreased. |

|

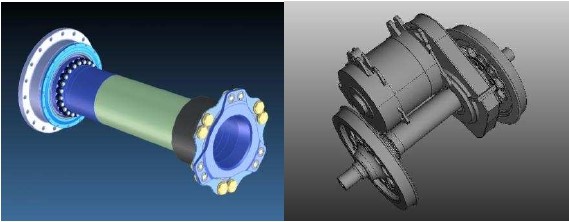

Innovation the locomotive engine Škoda 109 E |

Co-operation at locomotive engine (composite shaft) innovation |

|

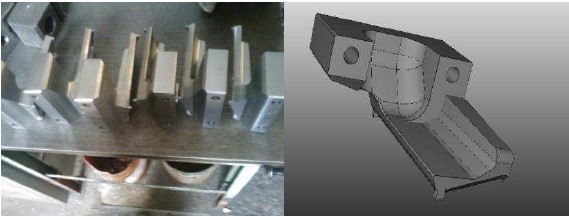

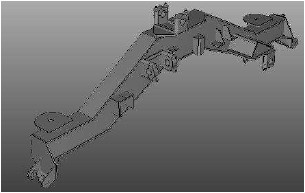

Innovation of machinig by the help of CAM 3D parts |

Innovation enables machining the complicated 3D parts of railway vehicles by the help of CAM system, and by this the castings and forgings were replaced. |

|

Innovation of shafts material |

Innovation consisted in the development of unique flexible composite transmission shaft, whereon was granted the patent (2009 – 344) and utility model (2009 – 21255, no. of protecting documentation 19823). |

|

Innovation of end truss jib |

The recent finished developing project is the innovation of end Arm no. 4, when the higher rigidity, operating reach and weight reduction was gained. This innovative project was a subject of the application for OPEI grant – Innovation programme. |

The examples of innovative products the DELTA HL company in the recent years

Innovation of quiding the telescopic jibs

Trolley bus TB 112 axle

The building machinery jibs from high-strength fine-grain steel S700 MC, S890 QL, S960 QL

Innovation the locomotive engine Škoda 109 E

Innovation of machining the complicated 3D parts of railway vehicles by the help of CAM (replacement of castings, forgings).